TYPES OF LEATHER

Oil pull-up Leather

Oil pull-up leather, also known as oiled or waxy leather, is a type of leather that is treated with oils and waxes during the tanning process. It is known for its unique appearance, durability, and ability to develop a rich patina over time. The production of oil pull-up leather involves applying a combination of oils, waxes, and dyes to the surface of the leather. These treatments penetrate the leather, providing it with a deep, lustrous colour and a distinctive pull-up effect. The pull-up effect refers to the leather becoming lighter in colour when stretched or folded, as the oils and waxes temporarily move away from the stressed area, creating a contrasting shade. The use of oils and waxes in oil pull-up leather provides several advantages. It enhances the leather’s natural characteristics, such as its softness, flexibility, and resistance to cracking or drying out. The oils and waxes also offer some water resistance, providing a certain level of protection against moisture and spills. Additionally, the leather’s surface can be easily revived and rejuvenated with a simple buffing or conditioning treatment. Over time, oil pull-up leather develops a unique patina, which is the natural ageing and wear that occurs on the surface. This patina adds character and depth to the leather, giving it a vintage and well-worn appearance. The patina is a desirable feature for many people, as it showcases the leather’s ageing process and individuality. Oil pull-up leather is commonly used in the production of high-quality leather goods, such as boots, shoes, bags, belts, and furniture upholstery. Its combination of durability, distinctive appearance, and the ability to age gracefully makes it a popular choice for those seeking a rugged and characterful leather material.

Marble-look Leather

Marble-look leather, also known as marbleized leather or veined leather, is a type of leather that is designed to resemble the appearance of marble stone. It is achieved through a specialized finishing process that creates a marbled or veined pattern on the surface of the leather. The process of creating marble look leather involves applying a combination of pigments, dyes and finishes to the leather’s surface. The application methods can vary but typically involve a combination of hand-painting, airbrushing, or digital printing techniques. The colours and patterns used aim to mimic the natural variations and veins found in marble stone. The result is a leather surface that features a unique and visually striking pattern reminiscent of marble. The patterns can range from subtle veins to bold and dramatic marble designs, depending on the desired effect. The finished leather may have a glossy or matte finish, depending on the type of coating or topcoat applied. Marble look leather is often used in luxury fashion accessories, such as handbags, wallets, and shoes, as well as in interior design applications like upholstery for furniture and automotive interiors. It offers a unique aesthetic that adds a touch of elegance and sophistication to leather products. It’s important to note that marble looks like leather is an artificial interpretation of marble’s appearance and does not have the same properties as genuine marble stone. The pattern is applied to the surface of the leather and does not affect the leather’s inherent qualities, such as its durability or texture. Overall, marble look leather provides a visually appealing alternative to traditional solid-colour leather, allowing designers to incorporate the beauty and elegance of marble into their leather creations.

Water-resistant Leather

Water-resistant Leather refers to a type of leather that has been treated or finished to have enhanced resistance to water absorption and damage. It is designed to repel or resist the penetration of water to a certain degree, providing a level of protection against moisture. Water resistance in leather can be achieved through various methods, including the use of specific tanning techniques, application of protective coatings or finishes, or incorporating water-repellent agents during the leather manufacturing process. These treatments help to create a barrier on the leather’s surface, preventing water from seeping into the material. Water-resistant leather offers several advantages. It helps to protect the leather from water stains, discoloration, and damage caused by prolonged exposure to moisture. It also makes the leather easier to clean and maintain since water-resistant coatings typically repel dirt and allow for easier spot cleaning. Additionally, water-resistant leather is generally more durable and long-lasting compared to untreated leather. It is important to note that water-resistant leather is not entirely waterproof. While it provides a level of protection against water, it may still absorb some moisture under prolonged exposure or in heavy rain conditions. Therefore, it is recommended to take appropriate care and avoid excessive exposure to water to maintain the leather’s water-resistant properties. Water-resistant leather finds applications in various products, such as outdoor footwear, jackets, bags, and accessories that are likely to be exposed to moisture or weather conditions. It provides a balance between the natural look and feel of leather while offering some protection against water-related damage.

Nappa Leather

Nappa leather, also known as Napa leather, is a type of high-quality, soft, and smooth leather that is highly regarded for its luxurious feel and fine grain. It is made from the hides of sheep, lambs, or goats, and is known for its supple texture and excellent durability. The term “Nappa” originates from the name of a region in Italy called Napa, which was renowned for its leather production. However, Nappa leather is not exclusive to Italy and can be produced in various parts of the world. Nappa leather undergoes a tanning process that utilizes chrome or vegetable tanning methods. This process enhances the leather’s strength and flexibility while preserving its natural characteristics. After tanning, the leather is typically treated with dyes and finishes to achieve the desired colour and appearance. One of the distinguishing features of Nappa leather is its exceptionally smooth and uniform grain. The surface of Nappa leather is often free from blemishes, scars, or noticeable imperfections, giving it a clean and elegant appearance. This makes it a popular choice for high-end leather goods, including luxury handbags, wallets, gloves, and automotive upholstery. Nappa leather is also valued for its softness and pliability. It has a natural elasticity that allows it to conform to the shape of objects or the body with ease. The suppleness of Nappa leather makes it comfortable to touch and wear. Due to its fine quality and premium attributes, Nappa leather is generally more expensive compared to other types of leather. It is sought after by those who appreciate the combination of softness, durability, and luxurious feel that Nappa leather offers. Overall, Nappa leather is a top-tier leather known for its softness, smooth grain, and high-quality craftsmanship. Its refined appearance and exceptional tactile qualities make it a popular choice for creating elegant and sophisticated leather products.

Split-Finished leather

Split-finished leather, also known as corrected grain leather, is a type of leather that is produced from the lower layers of the hide, specifically the split layer. The split layer is obtained by splitting the full-grain leather into two sections: the top-grain and the split. In the manufacturing process, the top-grain layer, which is the uppermost and most desirable part of the hide, is separated from the split layer. The split layer is then processed to create split-finished leather. The term “corrected grain” refers to the fact that the surface of the leather is corrected or modified to enhance its appearance. The split layer of the hide is generally less uniform in appearance and quality compared to the top-grain layer. It may have more natural imperfections, such as scars, scratches, or uneven textures. To improve the surface of the split leather, various corrective techniques are employed. These techniques involve sanding, buffing, or embossing the surface to create a more consistent and visually appealing appearance. After the corrective processes, a finish or pigment is often applied to the surface of the leather to provide colour and further enhance its appearance. This finish can be a dye, pigmented coating, or a combination of both. The finish adds a protective layer to the leather and can give it a uniform colour or texture. Split-finished leather offers a more affordable alternative to full-grain or top-grain leather, as the split layer is typically less expensive than the top-grain portion. It still maintains some of the desirable characteristics of leather, such as durability and strength, but may not possess the same level of natural grain and softness as higher-quality leather. Split-finished leather is commonly used in the production of upholstery, furniture, and lower-priced leather goods. Its corrected surface provides a consistent appearance and allows for a variety of finishes and textures. While it may not have the same premium qualities as full-grain or top-grain leather, split-finished leather can still be a practical choice for those seeking a more budget-friendly leather option.

Oil pull-up Leather

Oil pull-up leather, also known as oiled or waxy leather, is a type of leather that is treated with oils and waxes during the tanning process. It is known for its unique appearance, durability, and ability to develop a rich patina over time. The production of oil pull-up leather involves applying a combination of oils, waxes, and dyes to the surface of the leather. These treatments penetrate the leather, providing it with a deep, lustrous colour and a distinctive pull-up effect. The pull-up effect refers to the leather becoming lighter in colour when stretched or folded, as the oils and waxes temporarily move away from the stressed area, creating a contrasting shade. The use of oils and waxes in oil pull-up leather provides several advantages. It enhances the leather’s natural characteristics, such as its softness, flexibility, and resistance to cracking or drying out. The oils and waxes also offer some water resistance, providing a certain level of protection against moisture and spills. Additionally, the leather’s surface can be easily revived and rejuvenated with a simple buffing or conditioning treatment. Over time, oil pull-up leather develops a unique patina, which is the natural ageing and wear that occurs on the surface. This patina adds character and depth to the leather, giving it a vintage and well-worn appearance. The patina is a desirable feature for many people, as it showcases the leather’s ageing process and individuality. Oil pull-up leather is commonly used in the production of high-quality leather goods, such as boots, shoes, bags, belts, and furniture upholstery. Its combination of durability, distinctive appearance, and the ability to age gracefully makes it a popular choice for those seeking a rugged and characterful leather material.

Marble-look Leather

Marble-look leather, also known as marbleized leather or veined leather, is a type of leather that is designed to resemble the appearance of marble stone. It is achieved through a specialized finishing process that creates a marbled or veined pattern on the surface of the leather. The process of creating marble look leather involves applying a combination of pigments, dyes and finishes to the leather’s surface. The application methods can vary but typically involve a combination of hand-painting, airbrushing, or digital printing techniques. The colours and patterns used aim to mimic the natural variations and veins found in marble stone. The result is a leather surface that features a unique and visually striking pattern reminiscent of marble. The patterns can range from subtle veins to bold and dramatic marble designs, depending on the desired effect. The finished leather may have a glossy or matte finish, depending on the type of coating or topcoat applied. Marble look leather is often used in luxury fashion accessories, such as handbags, wallets, and shoes, as well as in interior design applications like upholstery for furniture and automotive interiors. It offers a unique aesthetic that adds a touch of elegance and sophistication to leather products. It’s important to note that marble looks like leather is an artificial interpretation of marble’s appearance and does not have the same properties as genuine marble stone. The pattern is applied to the surface of the leather and does not affect the leather’s inherent qualities, such as its durability or texture. Overall, marble look leather provides a visually appealing alternative to traditional solid-colour leather, allowing designers to incorporate the beauty and elegance of marble into their leather creations.

Water-resistant Leather

Water-resistant Leather refers to a type of leather that has been treated or finished to have enhanced resistance to water absorption and damage. It is designed to repel or resist the penetration of water to a certain degree, providing a level of protection against moisture. Water resistance in leather can be achieved through various methods, including the use of specific tanning techniques, application of protective coatings or finishes, or incorporating water-repellent agents during the leather manufacturing process. These treatments help to create a barrier on the leather’s surface, preventing water from seeping into the material. Water-resistant leather offers several advantages. It helps to protect the leather from water stains, discoloration, and damage caused by prolonged exposure to moisture. It also makes the leather easier to clean and maintain since water-resistant coatings typically repel dirt and allow for easier spot cleaning. Additionally, water-resistant leather is generally more durable and long-lasting compared to untreated leather. It is important to note that water-resistant leather is not entirely waterproof. While it provides a level of protection against water, it may still absorb some moisture under prolonged exposure or in heavy rain conditions. Therefore, it is recommended to take appropriate care and avoid excessive exposure to water to maintain the leather’s water-resistant properties. Water-resistant leather finds applications in various products, such as outdoor footwear, jackets, bags, and accessories that are likely to be exposed to moisture or weather conditions. It provides a balance between the natural look and feel of leather while offering some protection against water-related damage.

Nappa Leather

Nappa leather, also known as Napa leather, is a type of high-quality, soft, and smooth leather that is highly regarded for its luxurious feel and fine grain. It is made from the hides of sheep, lambs, or goats, and is known for its supple texture and excellent durability. The term “Nappa” originates from the name of a region in Italy called Napa, which was renowned for its leather production. However, Nappa leather is not exclusive to Italy and can be produced in various parts of the world. Nappa leather undergoes a tanning process that utilizes chrome or vegetable tanning methods. This process enhances the leather’s strength and flexibility while preserving its natural characteristics. After tanning, the leather is typically treated with dyes and finishes to achieve the desired colour and appearance. One of the distinguishing features of Nappa leather is its exceptionally smooth and uniform grain. The surface of Nappa leather is often free from blemishes, scars, or noticeable imperfections, giving it a clean and elegant appearance. This makes it a popular choice for high-end leather goods, including luxury handbags, wallets, gloves, and automotive upholstery. Nappa leather is also valued for its softness and pliability. It has a natural elasticity that allows it to conform to the shape of objects or the body with ease. The suppleness of Nappa leather makes it comfortable to touch and wear. Due to its fine quality and premium attributes, Nappa leather is generally more expensive compared to other types of leather. It is sought after by those who appreciate the combination of softness, durability, and luxurious feel that Nappa leather offers. Overall, Nappa leather is a top-tier leather known for its softness, smooth grain, and high-quality craftsmanship. Its refined appearance and exceptional tactile qualities make it a popular choice for creating elegant and sophisticated leather products.

Split-Finished leather

Split-finished leather, also known as corrected grain leather, is a type of leather that is produced from the lower layers of the hide, specifically the split layer. The split layer is obtained by splitting the full-grain leather into two sections: the top-grain and the split. In the manufacturing process, the top-grain layer, which is the uppermost and most desirable part of the hide, is separated from the split layer. The split layer is then processed to create split-finished leather. The term “corrected grain” refers to the fact that the surface of the leather is corrected or modified to enhance its appearance. The split layer of the hide is generally less uniform in appearance and quality compared to the top-grain layer. It may have more natural imperfections, such as scars, scratches, or uneven textures. To improve the surface of the split leather, various corrective techniques are employed. These techniques involve sanding, buffing, or embossing the surface to create a more consistent and visually appealing appearance. After the corrective processes, a finish or pigment is often applied to the surface of the leather to provide colour and further enhance its appearance. This finish can be a dye, pigmented coating, or a combination of both. The finish adds a protective layer to the leather and can give it a uniform colour or texture. Split-finished leather offers a more affordable alternative to full-grain or top-grain leather, as the split layer is typically less expensive than the top-grain portion. It still maintains some of the desirable characteristics of leather, such as durability and strength, but may not possess the same level of natural grain and softness as higher-quality leather. Split-finished leather is commonly used in the production of upholstery, furniture, and lower-priced leather goods. Its corrected surface provides a consistent appearance and allows for a variety of finishes and textures. While it may not have the same premium qualities as full-grain or top-grain leather, split-finished leather can still be a practical choice for those seeking a more budget-friendly leather option.

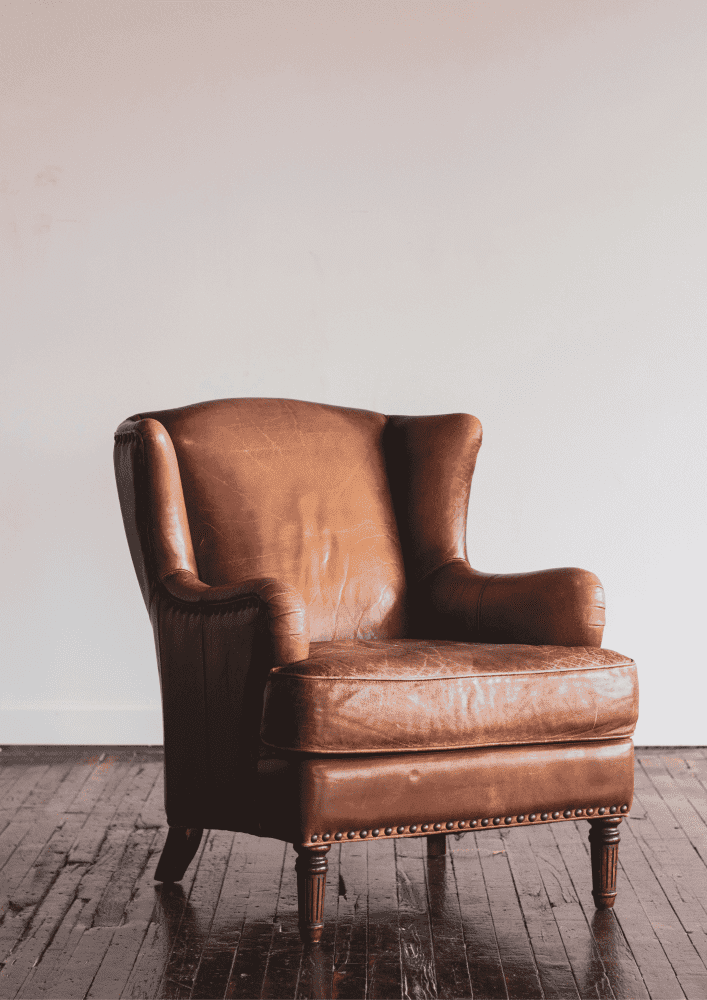

Leather For Upholstery

Full Grain Leather

Full-grain leather is considered the highest quality and most durable type of leather. It is made from the complete, unaltered grain of the hide, with all natural markings and imperfections intact. Full-grain leather develops a beautiful patina over time and is highly resistant to wear and tear.

Top Grain Leather

Top-grain leather is another popular choice for upholstery. It is made by splitting the top layer of the hide and sanding away any imperfections. Top-grain leather is slightly thinner and more pliable than full-grain leather but still retains its strength. It is often finished with a protective coating, making it easier to clean and maintain.

Corrected Grain Leather

Corrected grain leather is made from the lower layers of the hide. It undergoes a process where imperfections are sanded off, and an artificial grain is embossed onto the surface. Corrected-grain leather is more affordable than full-grain or top-grain leather, but it may not have the same natural look and durability.

Bonded Leather

Bonded leather is made by blending scraps of genuine leather with a bonding agent and synthetic materials. It is then embossed with a grain pattern. Bonded leather is a cost-effective option, but it is not as durable or long-lasting as other types of leather.

Nubuck Leather

Nubuck leather is created by sanding or buffing the outer side of a hide to produce a velvety texture. It has a similar appearance to suede but is more durable. Nubuck leather is soft and luxurious but requires regular maintenance to keep it looking its best.

Aniline Leather

Aniline leather is known for its natural look and feel. It is dyed with soluble dyes that penetrate the leather, allowing the natural grain and markings to show through. Aniline leather is very soft and comfortable, but it is susceptible to stains and fading.

Semi-Aniline Leather

Semi-aniline leather is similar to aniline leather but has a light protective coating applied to it. This coating provides some resistance to stains and fading while still allowing the natural characteristics of the leather to shine through.

Leather For Leather Goods

Full-Grain Leather

This is the highest quality and most durable type of leather. It is made from the top layer of the hide, which retains the natural grain and imperfections. Full-grain leather develops a beautiful patina over time and is known for its strength and longevity.

Top-Grain Leather

This type of leather is also made from the top layer of the hide, but it undergoes some surface treatments to remove imperfections and create a more uniform appearance. While it may not be as durable as full-grain leather, it is still of high quality and commonly used in leather goods.

Corrected-Grain Leather

This leather is produced by buffing or sanding the surface of full-grain or top-grain leather to remove imperfections. A finish is then applied to create a smooth and consistent appearance. Corrected-grain leather is often used in applications where a more uniform look is desired.

Suede Leather

Suede is made from the underside of the animal hide and has a soft and fuzzy texture. It is created by splitting the leather into layers, with the top layer used for full-grain or top-grain leather and the lower layer used for suede. Suede leather is commonly used for shoes, bags, and garments.

Nubuck Leather

Nubuck is similar to suede but is made from the top grain of the hide and is buffed to create a velvety texture. It is more durable than suede but requires regular maintenance to keep it looking its best. Nubuck leather is often used in high-end footwear and accessories.

Patent Leather

This is a type of leather that has been treated with a glossy and shiny finish. It is typically made from top-grain leather and has a distinctive reflective surface. Patent leather is commonly used in dress shoes, handbags, and other fashion accessories.

Exotic Leather

This category includes leathers made from the hides of exotic animals such as alligators, crocodiles, snakes, ostrich, and stingrays. Exotic leathers are highly sought after for their unique textures and patterns, and they are often used in luxury goods.

These are just a few examples of the many types of leather used in the production of leather goods. Each type has its own characteristics, strengths, and suitable applications, allowing for a wide range of choices in the world of leather craftsmanship.

Leather For Gloves

Gloving leather, also known as glove leather or glove-tanned leather, is a type of leather that is specifically processed and treated to make it suitable for manufacturing gloves. It is a soft and supple leather that offers excellent dexterity and flexibility, making it ideal for gloves intended for various activities. The process of gloving leather involves several steps to achieve its desired characteristics. First, high-quality animal hides, such as sheepskin or deerskin, are selected for their softness and pliability. Then, the hides undergo a tanning process, typically using vegetable tanning agents, which are known to produce a softer and more flexible leather compared to other tanning methods. After tanning, the leather is further processed through techniques like currying or drumming. Currying involves applying oils, waxes, or other conditioning agents to the leather surface, enhancing its suppleness and improving its water resistance. Drumming, on the other hand, involves tumbling the leather in a rotating drum to soften and break up the fibers, resulting in a smoother texture. The final product, gloving leather, is exceptionally soft, flexible, and lightweight, making it well-suited for glove making. It offers a comfortable fit and allows for excellent tactile sensitivity, which is important for tasks requiring precise hand movements, such as driving, gardening, or playing musical instruments. Gloving leather gloves are commonly used in fashion, sports, and occupational applications where dexterity and comfort are essential.

It’s worth noting that the term “gloving leather” primarily refers to the leather type used for gloves, and it should not be confused with a specific kind of leather originating from a particular animal. Different types of animal hides can be used to produce gloving leather, with sheepskin and deerskin being popular choices due to their inherent softness and pliability.

The choice of the best gloving leather can depend on personal preferences, specific requirements, and the intended use of the gloves. However, there are a few types of leather that are widely regarded as excellent choices for gloving leather due to their softness, flexibility, and durability. Here are some popular options:

Goat leather is popular option for gloving due to its unique characteristics. Here are some reasons why goat leather is commonly used for glove making: Goat leather gloves are commonly used in a range of applications, including fashion, outdoor activities, and work environments. They offer a good balance of comfort, durability, and flexibility, making them a reliable choice for many glove wearers.

Softness and Flexibility: Goat leather is naturally soft and supple, making it comfortable to wear. It has a smooth texture and moulds well to the shape of the hand, providing a snug fit. The softness and flexibility of goat leather allow for excellent dexterity and finger movement.

Durability: Despite its softness, goat leather is also known for its durability. It can withstand regular use and maintain its integrity over time. This makes it a reliable choice for gloves that need to withstand frequent wear and tear.

Water Resistance: Goat leather has inherent water-resistant properties, which can help protect the hands from moisture and light rain. While it is not entirely waterproof, goat leather offers some level of water resistance, making it suitable for various outdoor activities.

Breathability: Goat leather is breathable, allowing air circulation and preventing excessive sweating. This feature is particularly beneficial in gloves, as it helps maintain comfort and prevents the hands from becoming overly hot or clammy during extended use.

Grain Texture: Goat leather typically has a distinctive grain pattern, which adds visual appeal to the gloves. The grain texture can vary depending on the specific type of goat leather used.

Sheepskin Leather: Sheepskin leather is highly favoured for glove-making due to its exceptional softness and suppleness. It provides excellent dexterity and a comfortable fit. Sheepskin gloves are lightweight and offer good insulation, making them suitable for various activities.

Deerskin Leather: Deerskin leather is another popular choice for gloving leather. It is incredibly soft, and flexible, and has natural stretch properties. Deerskin gloves offer excellent grip and sensitivity, making them ideal for tasks requiring fine motor skills.

Peccary Leather: Peccary leather comes from the hides of wild boars, specifically the peccary species. It is known for its luxurious feel, durability, and natural elasticity. Peccary leather gloves are highly regarded for their comfort, style, and long-lasting performance.

Kangaroo Leather: Kangaroo leather is highly regarded for its strength, lightness, and exceptional abrasion resistance. It is one of the strongest types of leather available, making it suitable for gloves that require durability and protection. Kangaroo leather gloves offer excellent grip and flexibility.

Cabretta Leather: Cabretta leather, commonly derived from sheepskin, is particularly valued for its softness, fine grain, and durability. It is often used for golf gloves due to its excellent grip and tactile sensitivity.

It’s important to note that the quality and characteristics of gloving leather can vary depending on factors such as the tanning process, treatment, and craftsmanship. When choosing gloving leather, it’s advisable to consider your specific needs, budget, and personal preferences to find the best leather type for your desired gloves.

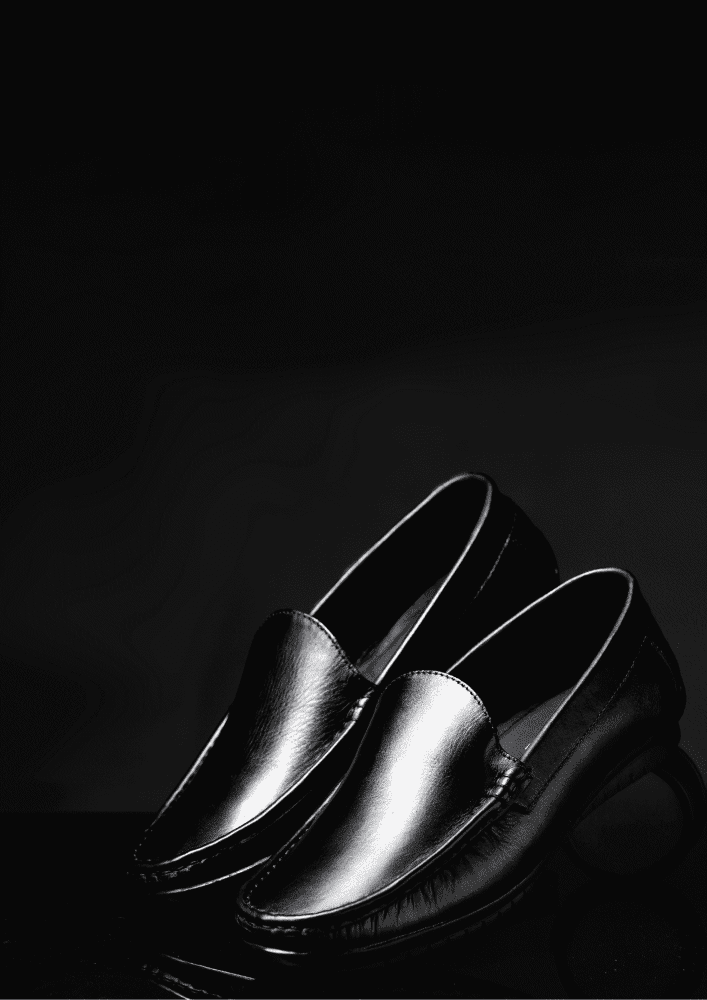

Leather For Shoes

Full-Grain Leather: This is the highest quality and most durable type of leather. It is made from the top layer of the hide, which has not been sanded or buffed to remove imperfections. Full-grain leather retains its natural grain and markings, making each pair of shoes unique. It is known for its strength, breathability, and ability to develop a beautiful patina over time.

Top-Grain Leather: This type of leather is also made from the top layer of the hide, but it undergoes a slight sanding or buffing process to remove imperfections. Top-grain leather is more uniform in appearance and slightly less durable than full-grain leather. However, it still maintains good quality and is commonly used in high-end footwear.

Corrected-Grain Leather: Corrected-grain leather is made from lower-quality hides that have more imperfections. The surface of the leather is sanded or buffed to remove those imperfections, and an artificial grain pattern is embossed onto it. Corrected-grain leather is often used in shoes where cost is a factor, and it may not have the same breathability or ageing characteristics as full-grain or top-grain leather.

Nubuck Leather: Nubuck leather is made from the outer side of the hide and is buffed or sanded to create a soft, velvety texture. It is similar to suede but with a finer grain. Nubuck leather shoes are stylish and luxurious but require extra care as they can be more prone to stains and water damage.

Suede Leather: Suede is created by splitting the underside of the hide to produce a soft and fuzzy nap. It is known for its comfortable feel and casual appearance. However, suede is more delicate than full-grain or top-grain leather and requires regular maintenance to keep it looking its best.

Patent Leather: Patent leather is a type of coated leather that has a shiny, glossy finish. It is typically made from corrected-grain leather and treated with a high-gloss lacquer or plastic coating. Patent leather shoes are often used for formal occasions and are known for their distinctive appearance.

Exotic Leathers: Various exotic animal hides are used to create unique and luxurious shoes. Examples include alligator, crocodile, ostrich, snake, and stingray leather. These leathers are known for their distinctive patterns and textures, but they tend to be more expensive and require specialized care.

Shell Cordovan: Shell cordovan is a specific type of leather made from the fibrous flat muscle (shell) found in horsehide. It is known for its exceptional durability, smooth surface, and ability to develop a beautiful patina over time. Shell cordovan shoes are highly regarded and sought after by shoe enthusiasts.

Nappa Leather: Nappa leather is a soft and supple type of full-grain leather. It is typically made from sheep or lamb hides and is known for its smooth texture and excellent flexibility. Nappa leather shoes are often used for dress shoes, as they provide a luxurious look and comfortable fit.

Chromexcel Leather: Chromexcel leather is a type of full-grain cowhide that undergoes a unique tanning process involving multiple layers of oils, waxes, and dyes. This process gives the leather a rich and glossy appearance, as well as excellent durability and water resistance. Chromexcel leather shoes are popular for their rugged yet refined aesthetic.

Veg-Tanned Leather: Vegetable-tanned leather is produced using natural tannins derived from plant materials, such as tree bark. This traditional tanning method results in a firm and durable leather that ages beautifully and develops a unique patina over time. Veg-tanned leather shoes are often used in artisanal and high-quality footwear.

Remember to consider your specific needs and preferences when selecting the type of leather for your shoes. These are just a few examples of leather types used in shoe manufacturing. The choice of leather depends on factors such as durability, desired aesthetics, price, and personal preference. It’s always a good idea to consider the specific leather type when purchasing shoes to ensure they meet your needs and expectations.